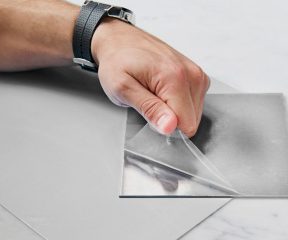

Stretch wraps are thin, elastic plastic films that are wrapped around products to secure them tightly. They are made from high-quality materials, such as linear low-density polyethylene (LLDPE), which provides them with excellent strength, puncture resistance, and stretchability. Stretch films or stretch wraps come in different widths, lengths, thicknesses, and colors, making them versatile enough to accommodate various products, shapes, and sizes.

Stretch films have become an essential component in the packaging industry due to their ability to secure and protect goods during transportation, storage, and handling. They offer several benefits, including increased product stability, protection against moisture and dust, and improved load containment. They also provide a cost-effective and efficient way of packaging products. At Behband, we recognize the importance of quality packaging solutions and strive to provide our clients with the best products possible. In this article, we will delve into the world of stretch films and explore how they can benefit businesses of all industries. We will also discuss the various types of stretch wraps that Behband offers, as well as the customization options available, and the measures we take to ensure the highest quality and durability for our products.

Benefits of Stretch Films or Stretch Wraps

Stretch films or stretch wraps offer several benefits to businesses. They help to protect products during transportation and storage, ensuring that they reach their destination in perfect condition. They also help to reduce the risk of damage to products, thereby reducing the cost of replacement. Stretch films also offer increased load stability, which ensures that products are stacked securely during transportation, reducing the risk of accidents.

Industries that benefit from using stretch wraps include food and beverage, pharmaceuticals, automotive, construction, and logistics, among others.

Types of Stretch Films or Stretch Wraps

Behband offers a wide range of stretch films to meet the diverse packaging needs of various industries. Our products include standard stretch films, pre-stretched films, colored films, UV stabilized films, and more. Each type of stretch film or stretch wrap is designed to cater to specific packaging needs, and we can help you determine which type is best suited for your products and industry.

Standard stretch films are versatile and can be used for various packaging applications. Pre-stretched films, on the other hand, offer greater load containment and require less energy to apply. Colored films are ideal for branding and marketing purposes, while UV stabilized films are suitable for products that require protection against UV light.

Customization Options

At Behband, we understand the importance of branding and marketing for businesses. That’s why we offer customization options for our stretch films, including branding and custom colors. Customization options can help businesses improve their branding and marketing efforts, making their products more recognizable and appealing to customers.

Quality and Durability

Quality and durability are crucial factors when it comes to packaging products. At Behband, we are committed to delivering the highest quality and most durable stretch films. We achieve this by using the best materials and subjecting our products to rigorous testing to ensure that they meet industry standards.

Applications of Stretch Films or Stretch Wraps

Stretch films or stretch wraps have various applications in different industries, such as pallet wrapping, bundling, and unitizing. Pallet wrapping involves securing products onto a pallet to protect them during transportation and storage. Bundling refers to securing items together for transportation or storage, while unitizing involves securing multiple products together to create a larger unit. These applications are common in industries such as food and beverage, pharmaceuticals, and retail.

For example, in the food and beverage industry, stretch films and stretch wraps are used to secure food items onto pallets and to wrap individual products such as meat, dairy, and frozen foods. In the pharmaceutical industry, stretch films and stretch wraps are used to secure products during transportation and storage to maintain their integrity and prevent contamination.

Sustainability of Stretch Films or Stretch Wraps

The environmental impact of packaging is a growing concern for businesses and consumers. At Behband, we understand the importance of sustainable packaging solutions and offer eco-friendly options for stretch films. Our sustainable options include using recycled materials and reducing waste in production.

Stretch Film Machinery and Equipment

The production of stretch films or stretch wraps requires specialized machinery and equipment. At Behband, we use state-of-the-art machinery and equipment to ensure the highest quality and consistency in our products. Our equipment includes extruders, winders, and slitters, which allow us to produce various types of stretch wraps to meet the needs of different industries.

Best Practices for Stretch Film or Stretch Wrap Usage

Proper usage of stretch films or stretch wraps is essential to ensure maximum effectiveness and safety. Businesses can optimize their usage of stretch films and stretch wraps by following proper wrapping techniques and storage. For example, wrapping pallets in a tight and uniform manner can prevent products from shifting during transportation, while storing stretch films and stretch wraps in a cool and dry area can prevent them from becoming brittle and losing their elasticity.

Proper Use and Handling of Stretch Films or Stretch Wraps

In addition to best practices for usage, it is essential to properly use and handle stretch films orstretch wraps to avoid common mistakes or issues. For example, overstretching the films or wraps can cause them to tear or break, while using the wrong type of stretch film can result in poor load containment.

Cost-effectiveness of Stretch Films or Stretch Wraps

Using stretch films or stretch wraps can be a cost-effective solution for businesses in the long run. These packaging solutions can help reduce the need for additional packaging materials, such as tape or strapping, and can prevent product damage during transportation and storage, which can result in costly returns or replacements. At Behband, we offer competitive pricing for our products and can help businesses save money on their packaging needs.

Industry Trends and Innovations

The stretch film or stretch wrap industry is constantly evolving, with new materials and technologies emerging to improve product performance and sustainability. At Behband, we stay up-to-date with the latest trends and innovations to provide the best possible products to our customers. For example, we offer biodegradable stretch films that are made from plant-based materials, which offer the same level of performance as traditional stretch films but with a reduced environmental impact.

Future of Stretch Films or Stretch Wraps

The future of stretch films looks promising, with advancements in technology and materials driving innovation in the industry. At Behband, we are committed to staying ahead of the curve in terms of innovation and product development. For example, we are exploring new materials such as graphene, which has the potential to enhance the strength and durability of stretch wraps.

Conclusion

Stretch films or stretch wraps are essential products in the packaging industry, offering several benefits to businesses. At Behband, we offer a wide range of stretch wraps to meet the diverse packaging needs of various industries. Our products are of the highest quality and durability, and we offer customization options to help businesses improve their branding and marketing efforts. Contact us today to learn more about our products and services.

Behband is an international manufacturing company that specializes in producing packaging products such as stretch wraps and packaging straps. With years of experience in the industry, Behband has been providing reliable and quality packaging solutions to various businesses worldwide.

Behband has been in the manufacturing industry for years, providing quality packaging products to businesses worldwide. We are committed to delivering reliable and innovative packaging solutions to meet the ever-evolving demands of the industry. Our goal is to ensure that our customers receive the best possible products and services that exceed their expectations.