Benefits of Industrial Stretch Film

Industrial stretch film offers several benefits to businesses, including increased product stability, protection against moisture and dust, and improved load containment. By securing products on pallets or bundles, industrial stretch film reduces the risk of product damage during transit or storage. Industries that benefit from using industrial stretch film include food and beverage, pharmaceuticals, logistics and distribution, manufacturing, and retail.

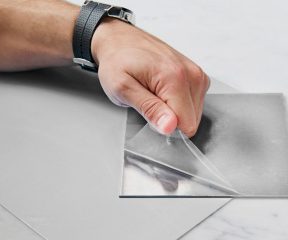

Types of Industrial Stretch Film

Behband offers various types of industrial stretch film, including cast stretch film, blown stretch film, pre-stretched film, and machine stretch film. Each type has unique characteristics and benefits, such as the thickness and elasticity of the film. Cast stretch film is ideal for wrapping irregularly shaped products, while blown stretch film is more durable and puncture-resistant. Pre-stretched film requires less force to stretch, making it easier to handle, and machine stretch film is suitable for high-volume operations.

Customization Options

Behband offers customization options for industrial stretch film, such as branding and custom colors. By adding their logo or brand colors to the film, businesses can improve their branding and marketing efforts. Customization options also allow businesses to differentiate themselves from their competitors and increase brand recognition.

Quality and Durability

Quality and durability are crucial factors in industrial stretch film. Behband ensures the highest quality and durability for its products through rigorous testing and the use of high-quality materials. Our industrial stretch wrap products are designed to withstand the rigors of transportation and storage, ensuring that products arrive at their destination intact and undamaged.

Applications of Industrial Stretch Film

Industrial stretch film has various applications, including pallet wrapping, bundling, and securing products for transportation. It is also used in the construction industry for wrapping and protecting building materials. Industries that use industrial stretch wrap for these applications include food and beverage, pharmaceuticals, logistics and distribution, manufacturing, and retail.

Industrial Stretch Film Machinery and Equipment

Behband uses advanced machinery and equipment in the production of industrial stretch wrap, ensuring the highest quality and consistency in the products. Our state-of-the-art production facilities enable us to produce industrial stretch film in various sizes and thicknesses to meet the needs of different industries and applications.

Sustainability of Industrial Stretch Film

Behband recognizes the importance of sustainable packaging solutions and offers various options for industrial stretch film, such as using recycled materials and reducing waste in production. We strive to minimize the environmental impact of our products and operations, and we encourage our customers to do the same.

Best Practices for Industrial Stretch Film Usage

To optimize the usage of industrial stretch film, businesses should follow these best practices:

Determine the Right Film Type for Your Application: The type of industrial stretch film you use should be based on the product being packaged, the mode of transportation, and the storage conditions. Choosing the right type of film can help you achieve better load containment and reduce the risk of product damage during transit.

Use Proper Wrapping Techniques: Using proper wrapping techniques can help you achieve the desired level of load containment and reduce the amount of film required for each pallet. To optimize the usage of industrial stretch wrap, businesses should ensure that the film is wrapped tightly around the pallet and the load is stable.

Minimize the Amount of Film Used: Using too much film can increase your packaging costs and result in unnecessary waste. To optimize the usage of industrial stretch film, businesses should use the minimum amount of film required to achieve the desired level of load containment.

Train Your Staff: Proper training is essential for ensuring that industrial stretch film is used effectively and safely. Train your staff on the proper use of the machinery, the different types of film, and the best wrapping techniques.

Monitor Your Film Usage: Monitoring your film usage can help you identify opportunities for optimization and cost savings. Keep track of the amount of film used per pallet and look for trends or patterns that could indicate areas for improvement.

Proper Storage: Proper storage of industrial stretch wrap can help you avoid damage to the film and ensure that it remains effective. Store the film in a cool, dry place, away from direct sunlight or heat sources.

Regular Maintenance of Machinery: Regular maintenance of machinery used for industrial stretch film production is essential for ensuring that the film is produced consistently and to the highest quality standards. Regular maintenance can also help you avoid costly downtime due to equipment failure.

Cost-effectiveness of Industrial Stretch Film

Using industrial stretch film can be a cost-effective solution for businesses in the long run. Although the initial investment may be higher than other types of packaging materials, the long-term benefits of using industrial stretch film can far outweigh the costs. For example, industrial stretch wrap can help reduce the risk of product damage during transit, which can result in fewer product returns and lower costs associated with damaged products.

In addition, industrial stretch film can help businesses reduce their packaging waste and improve their sustainability efforts. Using less packaging material can help reduce the amount of waste generated and lower disposal costs. This can also help businesses demonstrate their commitment to sustainability to customers and stakeholders.

Behband company offers competitive pricing for its industrial stretch film products. By working closely with customers to understand their unique packaging needs, Behband company can provide customized solutions that are both cost-effective and efficient.

Future of Industrial Stretch Film

Advancements in technology and materials are expected to have a significant impact on the future of industrial stretch film. New materials and technologies are being developed to improve the performance and sustainability of packaging materials. Behband company is committed to staying ahead of the curve in terms of innovation and product development. By investing in research and development, Behband company can provide customers with the latest and most innovative packaging solutions.

Industry Trends and Innovations

Current trends and innovations in the industrial stretch wrap industry include the use of new materials such as bio-based and recycled materials, as well as the development of high-performance films that offer superior load containment and protection. Behband Company stays up-to-date with the latest industry trends and innovations by investing in research and development, and collaborating with industry experts and partners. By doing so, the company is able to provide its customers with cutting-edge products that meet their evolving needs and requirements.

One trend that is gaining momentum in the industry is the use of biodegradable and compostable stretch films. These films are made from plant-based materials that break down naturally in the environment, reducing waste and pollution. Behband Company offers a range of sustainable stretch films that are made from biodegradable and compostable materials, and are ideal for businesses looking to reduce their environmental footprint.

Another trend in the industry is the use of automation and robotics in the production and application of stretch films. Automated packaging solutions not only increase efficiency and productivity, but also improve the accuracy and consistency of the packaging process. Behband Company is committed to adopting new technologies and processes that enhance its operations and customer experience, and is constantly exploring new ways to automate its production and delivery systems.

Regulations

The manufacturing and use of stretch films are regulated by various industry and government bodies, including the FDA, ASTM, and EPA. These regulations ensure that the films are safe for use and meet certain standards for quality and performance.

Behband Company complies with all relevant regulations and guidelines, and conducts rigorous testing and quality control procedures to ensure that its stretch films meet or exceed industry standards. The company also works closely with its customers to ensure that their packaging needs are met in a safe, compliant, and efficient manner.

Proper Use and Handling of Industrial Stretch Film

To ensure maximum effectiveness and safety, it is important for businesses to use and handle stretch films properly. Some best practices for using and handling stretch films include:

Choosing the right type of stretch film for the product and application

Ensuring that the stretch film is applied at the correct tension level

Avoiding overstretching the film, which can cause it to tear or lose its effectiveness

Properly securing the film to prevent shifting or unwrapping during transit

Using appropriate personal protective equipment when handling stretch films, such as gloves and safety glasses

By following these best practices, businesses can ensure that their products are properly packaged and protected during transit, reducing the risk of damage or loss.

Conclusion

In conclusion, industrial stretch films play a critical role in the packaging industry, offering a cost-effective and versatile solution for businesses of all sizes and industries. Behband Company is a leading manufacturer of high-quality stretch films, offering a wide range of products that meet the needs of its customers.

Whether businesses require standard or customized stretch films, sustainable packaging solutions, or expert advice and support, Behband Company has the expertise and resources to deliver. By partnering with Behband Company, businesses can benefit from superior product performance, reliable delivery, and exceptional customer service.